As cost-effective and durable system solutions for heavy-duty applications, the water-cooled, high-pressure boosters in the GIB series from BAUER KOMPRESSOREN support a wide and varied range of options for post-compression.

These multi-stage boosters combine high delivery rates at final pressures up to max. 420 bar with low power consumption.

Ideally matches pressure ratios of the individual compressor stages significantly reduce process costs for the post-compression of air, nitrogen, helium, argon and other noble gases.

The advanced version of the proven B-CONTROL MICRO compressor control. The B-CONTROL II features a 5.7″ colour touch screen display with 10 direct selection keys. Interaction between user and control is user-friendly and logical. The information on the display can be read off in plain text. Various languages are available for selection.

As well as supporting the control and monitoring of important unit functions, the B-CONTROL II also features user-friendly additional features such as a data logger, USB port and accessible interfaces such as Modbus, CAN Bus or Profibus. It can even be used for integrated control of an interconnected system with up to four compressors.

Additional sensors and devices can be connected, e.g. for monitoring intermediate pressures and temperatures. Remote data transfer via B-MESSENGER is supported as an option. The B-CONTROL II can be customised and expanded to meet your individual requirements – even if these involve controlling end-to-end system sequences.

For compressor units with intake pressure, the BK 23 to BK 52 block series feature a specially designed crankcase for uniform absorption of the internal gas forces

By using targeted water cooling between the interstage and afterstage coolers and valve heads, the system enables the majority of the heat produced to be absorbed by the cooling water. This maintenance-friendly cooling concept is suitable in particular for difficult spatial and ambient conditions where it would not be possible to use an air-cooled compressor.

The water-cooled series is characterised by its crankcase, which is pressure-resistant up to 16 bar. This makes compression to the required final pressure possible without blowby losses. At the same time, impurities in the process gas are minimised. Direct-coupled or V-belt drive solutions are available in horizontal or vertical format. The water-cooled high-pressure compressor series is ideal for installation under ambient and spatial in which air cooling would not be possible.

Liter per minute: 1330 - 22800

Bar: 90 - 520

Motor: 37 - 315 kW

Net weight: 1180 - 4330 kg

Below is a selection of equipment options for the water-cooled high-pressure booster

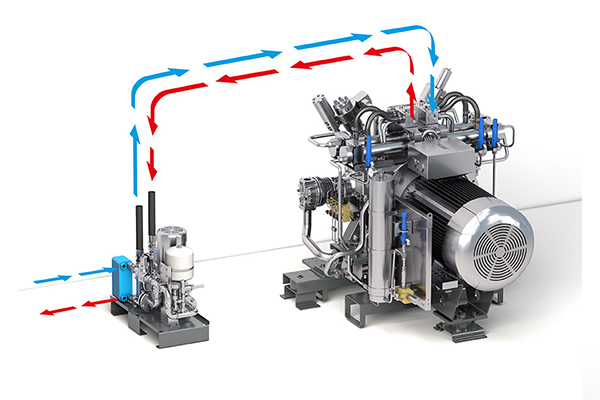

The plate heat exchanger set can be used to build a dedicated enclosed compressor cooling water circuit. In open cooling systems with stream water or sea water or open cooling towers, this is essential in order to operate the compressor with cooling water of suitable quality.

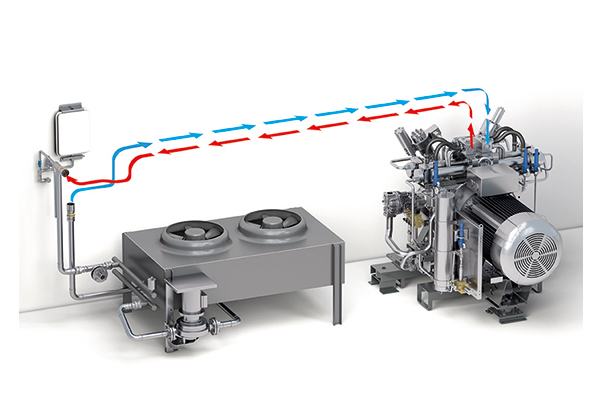

The set consists of an air-to-water heat exchanger which makes it possible to operate water-cooled compressor units independently of a water supply.

Compressor units by BAUER KOMPRESSOREN can be supplied with explosion protection and conforming to ATEX directives.

Intake pressure reduction ensures that the compressor takes in the gas at the appropriate pressure. Integrated safety valves and pressure monitoring provide an effective means of ensuring that the permissible intake pressure is not exceeded or undershot

Bay Kompressor ApS

Fuglebækvej 4A

DK-2770 Kastrup, Denmark

VAT: 28308213

Meet us at Facebook.

Copyright © 2020 Bay Kompressorer. Alle rettigheder forbeholdes – Design by DAN®