The VERTICUS series has been developed and built specifically to meet high performance requirements in continuous operation in professional applications.

The new VERTICUS combine the legendary BAUER compressor blocks with improved components and ultra-modern design! During the redesign, the focus was on ergonomics, making operation as easy as possible, reducing noise and boosting efficiency.All control elements that are important for everyday operation are ergonomically arranged and easily accessible from the front. The compressor control monitors the fill level and informs the operator in good time if the condensate needs to be emptied.The advanced B-CONTROL MICRO is more powerful and ready to communicate with the B-APP for remotely controlling and monitoring the compressor.

The VERTICUS breathing air compressors are available in versions for 225 and/or 330/350 bar as well as in a version for up to 420 bar. The high modularity of the VERTICUS series means that the units can easily be adapted to provide the best possible solution to your requirements and wishes.

The compressor stages, which are located on sides of the compressor blocks, are the key to optimum smooth running and high efficiency.The free-standing cylinders are easy to access and maintain. They are ideally positioned in the cooling air flow. The generous dimensioning of all bearings enables the blocks to achieve a service life in excess of 30,000 hours.The bearings are characterised by low heat generation, low friction values and low power losses.With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces.

When used in conjunction with original BAUER filter cartridges, the P 61 purification system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ of air can be treated.

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the intelligent control and reliable monitoring of all basic functions.Interaction between user and control is user-friendly and logical. The information on the display can be read off in plain text. Various languages are available for selection.Additional benefit: interfacing with external input/output signal encoders is possible at any time, as is interconnected operation or the connection of an external display unit.

The automatic condensate drain automatically removes the condensate that forms during compression (water/oil mixture) from the intermediate separators and the final separator and collects it in a condensate vessel.The newly developed and patented B-DRAIN automatic condensate drain uses individually controlled solenoid valves to ensure reliable, automatic condensate removal from the compressor separators.The innovative design enables condensate to be drained in a gentle, controlled manner while minimising the pressure drop. This saves energy and helps to increase the efficiency of the compressor unit. At the same time, the new B-DRAIN is much quieter than conventional solutions.A condensate vessel with 40% more capacity is integrated in the housing of the MINI-VERTICUS resp. VERTICUS. The compressor control monitors the fill level and informs the operator in good time if the condensate needs to be emptied

The integration of a motor rocker means that the tension of the V-belt no longer has to be adjusted.

Below is a selection of equipment options for the VERTICUS compressor

Super Silent housing reduces the noise level of the compressor unit and makes the unit compatible for operation in working environments where noise is a key concern. For units in the (MINI-) VERTICUS series, Super Silent sound insulation can be retrofitted on request.

When used in conjunction with original BAUER filter cartridges, the P 61 purification system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014.

B-APP allows users to remotely control and monitor compressors with the new B-CONTROL MICRO. B-APP also offers additional features such as product-specific news, videos, an integrated dealer search function and calculation tools. Available in the AppStore (iOS) and on GooglePlay (Android)

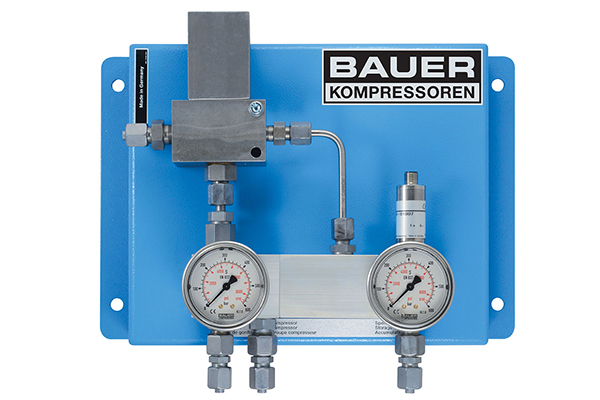

An automatic selector unit supports fully automatic switch-over between BAUER high-pressure storage units and the compressor unit.

As an option, the B-DETECTION PLUS i gas measurement system can be integrated into the compressor. This permits the monitoring of all gases required by DIN EN 12021:2014.

In environments in which ambient temperatures are high in particular, the B-KOOL refrigeration dryer extends filter capacity almost beyond belief. Operators benefit from much lower filter cartridge usage and storage costs in addition to longer interruption-free operation

The compressor and up to 2 storage bottles each with a geometric capacity of 50 or 80 litres are installed on the extended base frame, making this a turnkey system.

The optional pressure reducer enables simultaneous filling of 200 and 300 bar cylinders.

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve and outputs a warning on the display or the compressor control in advance of when the filter cartridge should be changed. B-SECURUS automatically switches the compressor unit off when the cartridge reaches saturation point.

.jpg)

The advanced version of the proven B-CONTROL MICRO compressor control. The B-CONTROL II features a 5.7″ colour touch screen display with 10 direct selection keys. Interaction between user and control is user-friendly and logical. The information on the display can be read off in clear text. Various languages are available for selection. As well as supporting the control and monitoring of important system functions, the B-CONTROL II also features additional user-friendly features.

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side

Optional oil level monitoring system for safely switching off the compressor unit when the oil level is low. If the oil level reaches the minimum mark, this is displayed on the control and the compressor is switched off automatically for safety reasons. This option is particularly recommended for compressor units in continuous operation

The new MINI-VERTICUS & VERTICUS Series from BAUER KOMPRESSOREN set the standards of the future for stationary high-pressure compressor systems. The series combines the quality and reliability of the preceding stationary compressor series with an all-new design, B-APP smartphone connection, online air quality monitoring and outstanding ergonomic features.

Bay Kompressor ApS

Fuglebækvej 4A

DK-2770 Kastrup, Denmark

VAT: 28308213

Meet us at Facebook.

Copyright © 2020 Bay Kompressorer. Alle rettigheder forbeholdes – Design by DAN®