DEN KRAFTFULDE FYLDESTATION

The KAP-LINE breathing air compressors by BAUER KOMPRESSOREN impress by combining unmistakable BAUER strengths and outstanding charging rates with compact dimensions.

Their horizontal design, incredible corrosion resistance and low centre of gravity mean that they are capable of continuous operation in a wide and varied range of mobile, marine and stationary applications even under the harshest of conditions.

The compressor stages, which are located on sides of the compressor blocks, are the key to optimum smooth running and high efficiency. The free-standing cylinders are easy to access and maintain. They are ideally positioned in the cooling air flow. The generous dimensioning of all bearings enables the blocks to achieve a service life in excess of 30,000 hours. The bearings are characterised by low heat generation, low friction values and low power losses. With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces.

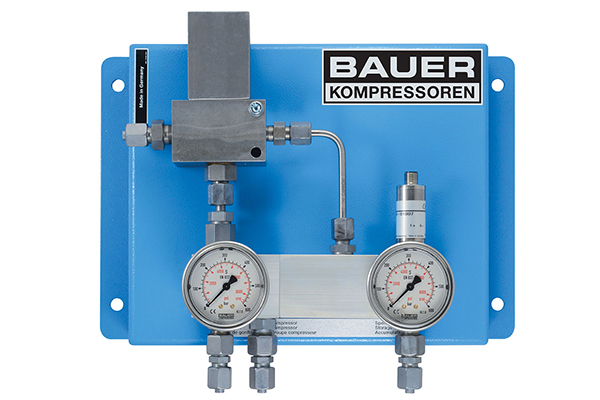

With two filter housings, additional oil and water separator and pressure retention check valve, this system can be relied upon to keep your breathing air clean. A type-tested and sealed final pressure safety valve optimises operational safety. 2200 standard cubic metres of air can be treated.

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the intelligent control and reliable monitoring of all basic functions. Interaction between user and control is user-friendly and logical. The information on the display can be read off in plain text. Various languages are available for selection.

Additional benefit: interfacing with external input/output signal encoders is possible at any time, as is interconnected operation or the connection of an external display unit.

When used in conjunction with original BAUER filter cartridges, the P 61 or P 81 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ (P 61) or 5200 m³ (P 81) of air can be treated.

The electronic control with additional monitoring electronics switches the compressor off automatically when the final pressure is reached in the system, measures operating hours and oil pressure, and displays the current operating status. The battery charge status can also be read off from the control box.

Below is a selection of equipment options for the KAP-LINE compressor

n the case of operation in locations where air humidity is high (tropical regions, for example), we recommend installing a separator downstream of the first compressor stage. This can extend the service life of the unit and reduce maintenance costs.

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve and outputs a warning on the display or the compressor control in advance of when the filter cartridge should be changed. B-SECURUS automatically switches the compressor unit off when the cartridge reaches saturation point.

The intermediate pressure gauges show the operating pressure of the individual compressor stages. This information about the pressure is used to check the corresponding stage valves (inlet and outlet) for leaks so that potential faults can be detected quickly. The intermediate pressure gauges are installed inside the compressor housing.

.jpg)

The advanced version of the proven B-CONTROL MICRO compressor control. The B-CONTROL II features a 5.7″ colour touch screen display with 10 direct selection keys. Interaction between user and control is user-friendly and logical.

An automatic selector unit supports fully automatic switch-over between BAUER high-pressure storage units and the compressor unit.

In environments in which ambient temperatures are high in particular, the B-KOOL refrigeration dryer extends filter capacity almost beyond belief. Operators benefit from much lower filter cartridge usage and storage costs in addition to longer interruption-free operation.

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2.

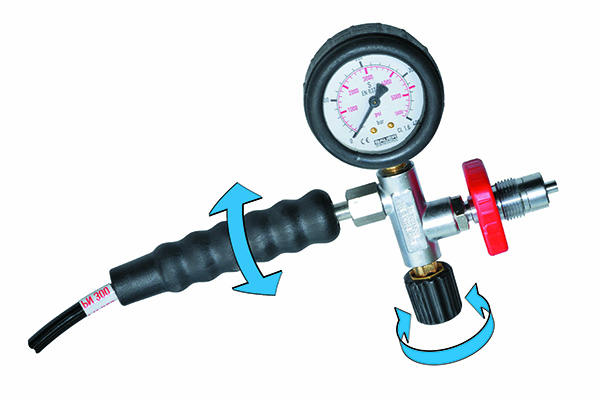

Filling devices with 4 or 6 filling valves are available as optional extras. Pressure range: PN 200 and/or PN 300 bar.

Bay Kompressor ApS

Fuglebækvej 4A

DK-2770 Kastrup, Denmark

VAT: 28308213

Meet us at Facebook.

Copyright © 2020 Bay Kompressorer. Alle rettigheder forbeholdes – Design by DAN®