The breathing air compressors in the PE-VE series are characterised by their impressive peak free air delivery rates of up to 850 l/min.

Professionally customised to meet individual needs and FAD requirements in breathing air applications, the PE-VE units offer practical equipment, typical BAUER quality and certified safety for reliable stationary operation.

The BAUER IK 120 and IK 12.14 compressor blocks are used for breathing air units and industrial units. Their durability, reliability and high-quality design provide the basis for fault-free operation of the compressor. With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces. Furthermore, wear-resistant piston rings in the final stage minimize running costs. Stainless steel cooling ribs provide the basis for particularly efficient cooling and thus very long service life.

The compressor stages, which are located on sides of the compressor blocks, are the key to optimum smooth running and high efficiency. The free-standing cylinders are easy to access and maintain. They are ideally positioned in the cooling air flow. The generous dimensioning of all bearings enables the blocks to achieve a service life in excess of 30,000 hours. The bearings are characterised by low heat generation, low friction values and low power losses. With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces.

When used in conjunction with original BAUER filter cartridges, the P 42 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 1550 m³ of air can be treated.

1If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

When used in conjunction with original BAUER filter cartridges, the P 61 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ of air can be treated.

1 If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the intelligent control and reliable monitoring of all basic functions. Interaction between user and control is user-friendly and logical. The information on the display can be read off in plain text. Various languages are available for selection. Additional benefit: interfacing with external input/output signal encoders is possible at any time, as is interconnected operation or the connection of an external display unit.

The integration of a motor rocker means that the tension of the V-belt no longer has to be adjusted.

Below is a selection of equipment options for the PE-VE compressor.

Super Silent compressors benefit from fully noise-damped cladding and optimised cooling air supply.

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve and outputs a warning on the display or the compressor control in advance of when the filter cartridge should be changed. B-SECURUS automatically switches the compressor unit off when the cartridge reaches saturation point. The B-SECURUS filter monitoring unit can only be used in conjunction with P 41/P 42/P 61/P 81 filter systems and external BAUER filter systems.

The filling device consists of four flexible UNIMAM high-pressure filling hoses and one filling valve each for 200 and 300 bar. The integrated final pressure gauge makes it easy to read off the final pressure.

In environments in which ambient temperatures are high in particular, the B-KOOL refrigeration dryer extends filter capacity almost beyond belief. Operators benefit from much lower filter cartridge usage and storage costs in addition to longer interruption-free operation.

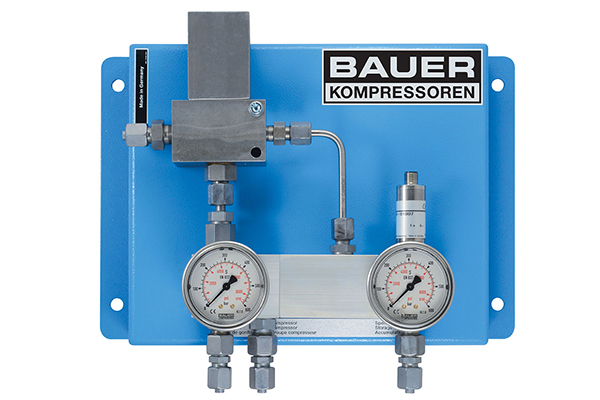

An automatic selector unit supports fully automatic switch-over between BAUER high-pressure storage units and the compressor unit

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side

Bay Kompressor ApS

Fuglebækvej 4A

DK-2770 Kastrup, Denmark

VAT: 28308213

Meet us at Facebook.

Copyright © 2020 Bay Kompressorer. Alle rettigheder forbeholdes – Design by DAN®