The PE-MVE from BAUER is the compact complete solution in a vertical format for all applications requiring medium delivery rates. Equipped with noise insulation housing as standard, the PE-MVE is ideal for use in environments where noise is a key concern and for customers who need reliable and durable service combined with low running costs.

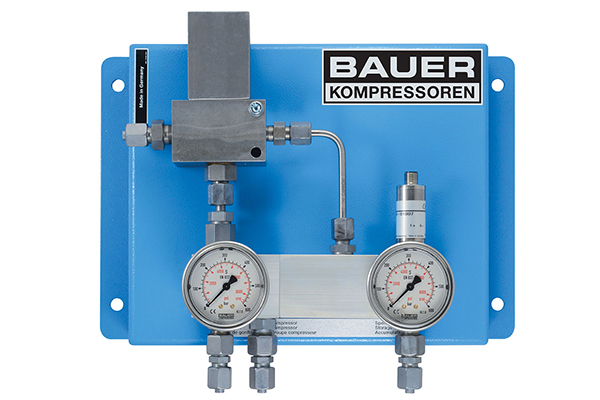

What’s more, the high-pressure compressors are already equipped with an automatic condensate drain and easy-to-use BHW CONTROL, which has a fully automatic mode for filling storage bottles.

The BAUER IK 120 series compressor block has been designed for the most demanding professional applications. Dimensioned for more than 30,000 operating hours, it has proven its worth in thousands of application scenarios. With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces. Furthermore, wear-resistant piston rings in the final stage minimize running costs. The compressor block is both efficient and reliable. Stainless steel cooling ribs on the cooler in the final stage provide the basis for particularly efficient cooling and thus very long service life

The Super-Silent cladding, which is installed as standard, impresses with its low noise level for working environments in which noise is a key concern and flexible installation options.

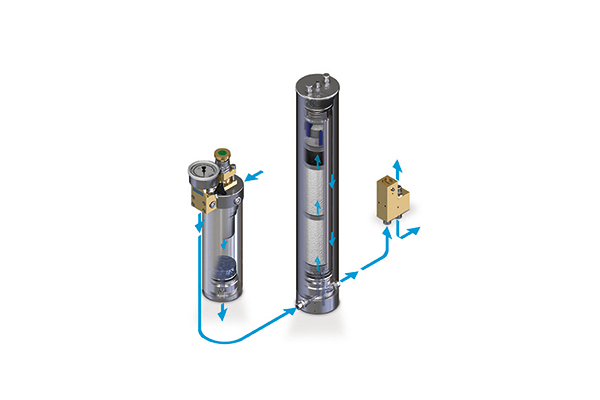

When used in conjunction with original BAUER filter cartridges, the P 31 filter system with integrated oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 600 m³ of air can be treated..

The electric control with additional monitoring electronics switches the compressor off automatically when the final pressure is reached in the system, measures operating hours, displays the current operating status and is equipped with a phase monitoring.

High-quality UNIMAM high-pressure filling hoses made from food-safe and long-life hose material make for flexible and safe handling. Swivel hose connections enable the filling valve to be connected to the breathing air cylinder quickly, easily and safely.

The automatic condensate drain is controlled via the electronic control system. The condensate produced can be collected in a condensate tank for disposal in an environmentally-friendly way.

The integration of a motor rocker with V-belt tensioner means that the tension of the V-belt no longer has to be adjusted.

Below is a selection of equipment options for the PE-MVE compressor.

The operating hours and the current level of cartridge saturation are displayed on the unique B-TIMER mini-computer. The B-TIMER flashes when a cartridge change is due. At the same time, the purchase order of the filter cartridge required is shown on the display. This ensures that the very best use is made of the filter’s capacity at all times.

ECURUS is an electronic filter cartridge saturation control which continuously monitors the ability of the final filter cartridge to dry breathing air in accordance with the standard EN 12021:2014.

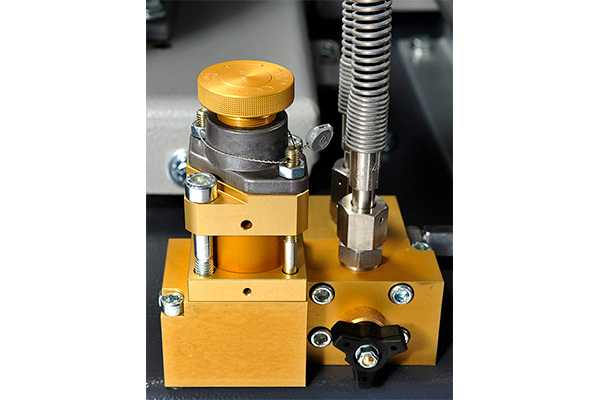

Adding the optional switch-over device makes switching from 200 to 300 bar and vice versa easy and flexible. The switch-over device enables breathing air cylinders to be filled with both 200 bar and 300 bar.

NWhen used in conjunction with original BAUER filter cartridges, the P41 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 1550 m³ of air can be treated.

An automatic selector unit supports fully automatic switch-over between BAUER high-pressure storage units and the compressor unit.

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side

Bay Kompressor ApS

Fuglebækvej 4A

DK-2770 Kastrup, Denmark

VAT: 28308213

Meet us at Facebook.

Copyright © 2020 Bay Kompressorer. Alle rettigheder forbeholdes – Design by DAN®